The Syracuse University Physics Department Machine Shop is an essential facility for the experimental physics research mission of the department. We often do not highlight this resource or the amazing work they do, but this year, we needed to talk about some of the wonderful and sometimes crazy things that happen in our shop! This article is meant to highlight their work and alert the community about some possible challenges that lie ahead and how we plan to tackle them.

New Science

Over the past year, the machine shop has made some nice science happen, supported the students with the tradition of Mrs. Jennings’s Wooden Leg, and discovered (re-discovered) the hidden acid pit in the physics building. A new addition to the machine shop is the 3D printer. Purchased in summer 2021 with Physics Department gift funds (thank you to those who donate to the Physics Department General Fund!). It is now set up and ready to go. It is used for fast design and mock-ups for scientific research. Faster and less durable, the machine can print out prototypes using multiple types of plastic to quickly assess the size, shape, and functionality of parts before milling or lathing from aluminum or other more expensive materials.

Some of the print jobs want the final product to be plastic, such as strange-shaped objects for students to use to understand concepts such as center of mass. One very cool aspect is the ability to create interlocking or mobile parts that are printed together, such as chains, gears, or springs. These aspects make the 3D printer unique among the shop’s many machines for creating scientific and teaching implements.

Affiliated faculty member, Steve Penn, works with Phil Arnold, postdoc Satoshi Tanioka, graduate student Nick Didio, and David Pratt (left to right) on a part that was 3D printed for the gravitational waves group.

Celebrations

With our return to in person work and learning, it was essential that we bring back the traditions that make getting a PhD from Syracuse University Physics special. One of the most exciting traditions is the mounting of your commemorative plaque on Mrs. Jennings’s wooden leg. After each thesis defense for the experimental students, they have an after party in the shop where they are presented with a commemorative plaque and allowed to affix the plaque onto the wooden leg. Unlike in the past, when students had to climb to screw in the plaque, we now use a step ladder to get to the location they desire. This is much safer! We do still have students climb to place a greasy thumb print onto the ceiling. This task is far less taxing and only needs one hand to apply the thumb print!

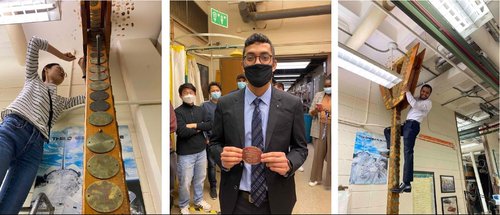

Mengqi Xu ’21 PhD, Sumon Sahu ’21 PhD, and Ali Imran ’22 PhD celebrating their PhD defenses with Mrs. Jennings Wooden Leg. Mengqi is standing on the step ladder to screw her plaque into place. Sumon is showing off his plaque with smiling lab mates behind him. Ali is climbing the telephone pole spikes to place his greasy thumb print on the ceiling.

To learn more about this cherished Physics tradition, read the article by Physics alum Al McRae "Mrs. Jennings Wooden Leg - Charlie Johnston’s Legacy"

Surprises

This year, we discovered a new part of the shop – the acid pit! It was discovered when one of our several waste disposal systems backed up and flooded several labs in the sub-basement. Apparently, we were flushing wastewater into a system used to neutralize acid. This was unknown to us and to the Syracuse University facilities people! Luckily, the wastewater was for cooling, and was not filled with acid or other harmful chemicals. The back-up occurred because of years of neglect and not cleaning the system. It was discovered that, in the farthest reaches of the area holding scraps and other materials, there is literally a pit lined with limestone. The limestone is there to neutralize acids and bases before they get sent into waste. The pit was covered with a large plate and forgotten. It was literally supporting the weight of several large shelves holding supplies. This all had to be moved so that a crew could come to clean and service the pit. We now have fresh limestone liner and clear lines to feed the pit. We will also try very hard not to forget the acid pit is there, to ensure that it is properly maintained regularly!

Challenges

In the past few years, the shop has seen some changes. In August 2019, there were four staff members in Physics who were affiliated with the shop. The building manager, Lou Buda, was a long-time Physics staff member essential for many experimental designs and problems solved throughout the building to facilitate research. With his retirement in February 2020, just before the pandemic broke, we had three people in the shop. They were Charlie Brown, Experimental Machinist, Phil Arnold, Lab Assistant, and David Pratt, a machinist hired by the high energy particle physics group working on the Large Hadron Collider beauty (LHCb) measurements. This past year, Charlie Brown also retired, and we were able to hire David Pratt as his replacement, bringing the shop staff down to two.

As some of you may be aware, machining is a dying art, and we desperately need a new generation of experts to ensure that we can continue to actually build things in the future. To this end, the Syracuse University Physics department developed a co-op program partnering with Onondaga Community College to bring machinists to the physics department to learn how the shop runs. This program launched this past summer. If funding allows it, we will continue this partnership to be able to offer training opportunities to students that are interested with the goal of developing more machinists for our department and elsewhere in the future. As we expect both David and Phil to retire in the next few years, this program is essential to keeping the shop running for our science and teaching missions. If you are interested in learning more or supporting this endeavor, please reach out to us.